ANSYS SOLAR AND ALTERNATIVE ENERGY SIMULATION SOLUTIONS

Solar power will be one of the most important technologies in meeting our energy needs of the future. Taking advantage of both the bountiful energy of the sun and advancements in thin film manufacturing in the semiconductor industry, solar power is set to be as ubiquitous as plants and computers. In this competitive market, the best engineered products will stand out and Ansys is the industry leader in simulating reliability and efficiency.

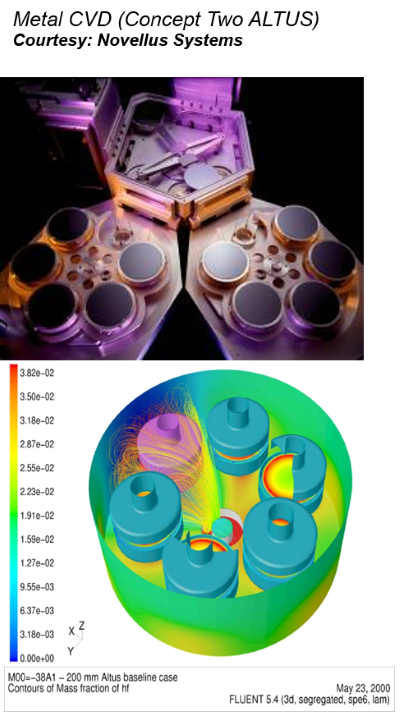

For multiphysics process conditions simulation, Ansys is the market leader. The tool of choice for the semiconductor manufacturing processes that the solar industry shares in common, Ansys is the trusted tool for process condition simulation. From sensitive deposition chambers to crystal formation simulation, Ansys ensures precise and efficient manufacturing.

The Ansys suite of tools is well suited for the following applications and more:

- Thin film deposition

- Process chambers

- Thermal stress from CTE miss-match

- Czochralski crystal formation

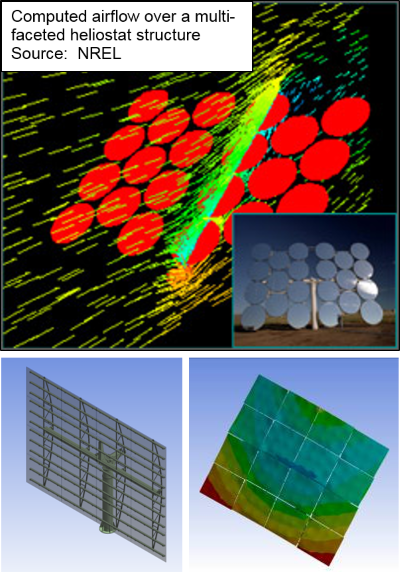

Solar power equipment is exposed to a diverse array of operating conditions throughout the world. Keeping the sensitive components working and working efficiently is a design challenge that can’t be ignored. The use of simulation early on in the design process will ensure that problems are fixed cheaply in the lab or computer, not out in the field at a great cost.

In the relatively young and fast moving solar energy market, innovation will separate the best companies from the rest. At the scale of large solar installations, small edges in performance or cost can make all the difference. Companies that can harness the full power of Ansys simulation will bring the best products to market and gain a well deserved reputation for reliability.

Ansys Simulation is commonly used for simulating the following in the solar industry:

- Wind loading through Fluid Structure Interation (FSI)

- Thermal cycling

- Dynamic and random loads such as vibration

- High and low cycle fatigue

- Multiphysical simulation of busbars

In the solar industry a small edge in the quality of hundreds or thousands of panels can make a big difference. Parametric simulation can be used in a variety of ways to shorten the product life-cycle and to converge on the optimal design. Changing a parameter value in the simulation will be more cost effective than building and testing a new prototype and this allows many more designs to be tested. This order of magnitude increase on the number of cases to simulate allows entirely new types of simulations to be performed, improving the design in new ways:

In the solar industry a small edge in the quality of hundreds or thousands of panels can make a big difference. Parametric simulation can be used in a variety of ways to shorten the product life-cycle and to converge on the optimal design. Changing a parameter value in the simulation will be more cost effective than building and testing a new prototype and this allows many more designs to be tested. This order of magnitude increase on the number of cases to simulate allows entirely new types of simulations to be performed, improving the design in new ways:

- Virtual prototyping through parametric analysis

- Multiobjective optimization

- Robust & Reliability studies through stochastic design parameters

![Ansys-elite-channel-partner-horizontal-reversed[1]](https://www.ozeninc.com/uploads/2022/06/Ansys-elite-channel-partner-horizontal-reversed1.png)