FEA Simulation Consulting

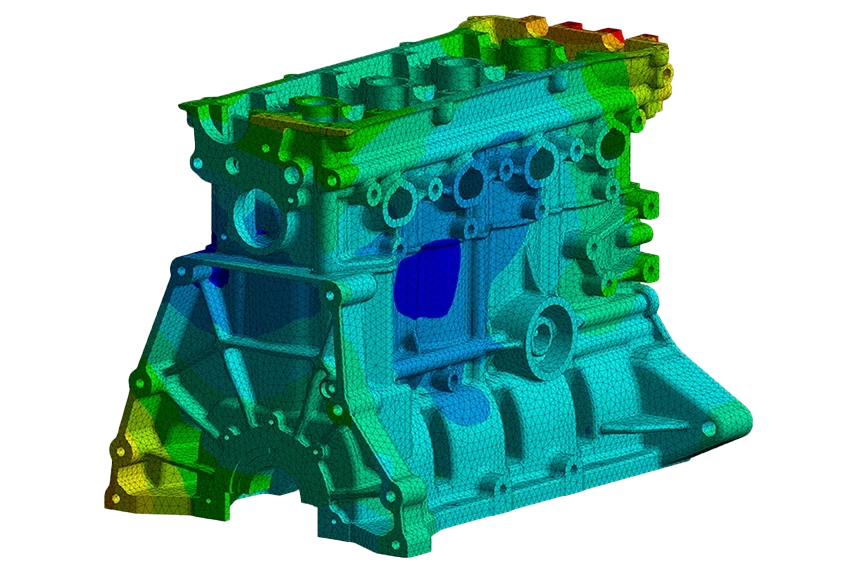

At Ozen Engineering, we offer advanced finite element analysis (FEA) simulation consulting, harnessing the power of Ansys Mechanical, Ansys LS-DYNA, Ansys Autodyn, and more. Our seasoned FEA consultants combine deep knowledge with practical expertise to optimize your structural analysis processes.

Our solutions include:

- In-depth Structural Analysis and Design

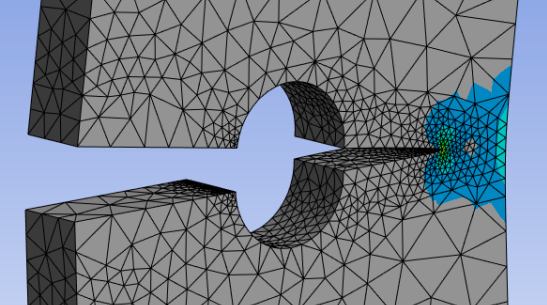

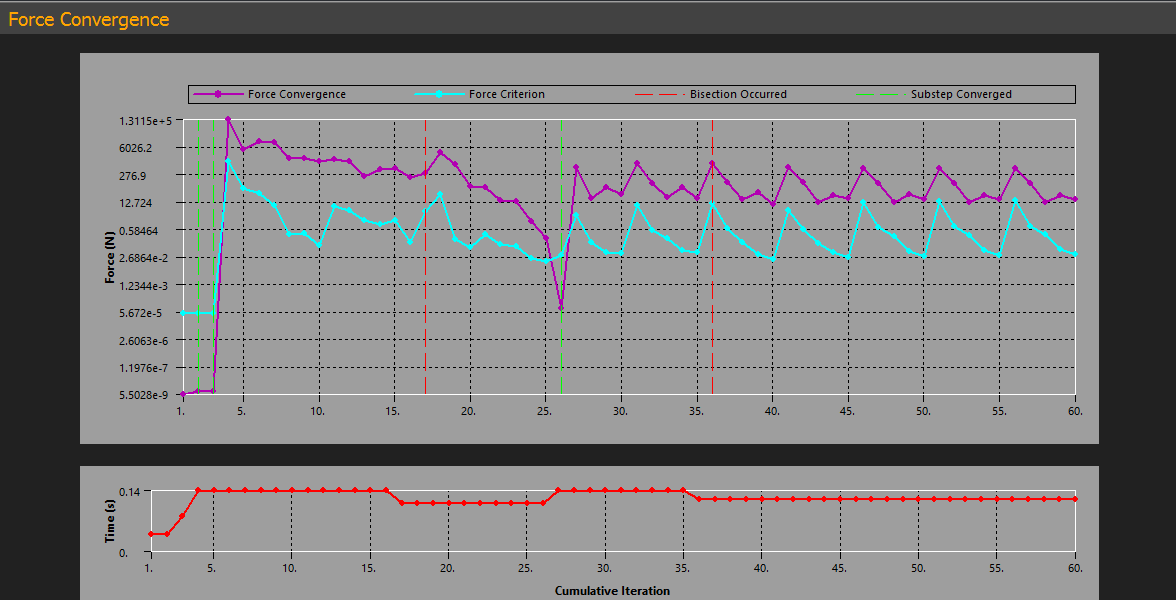

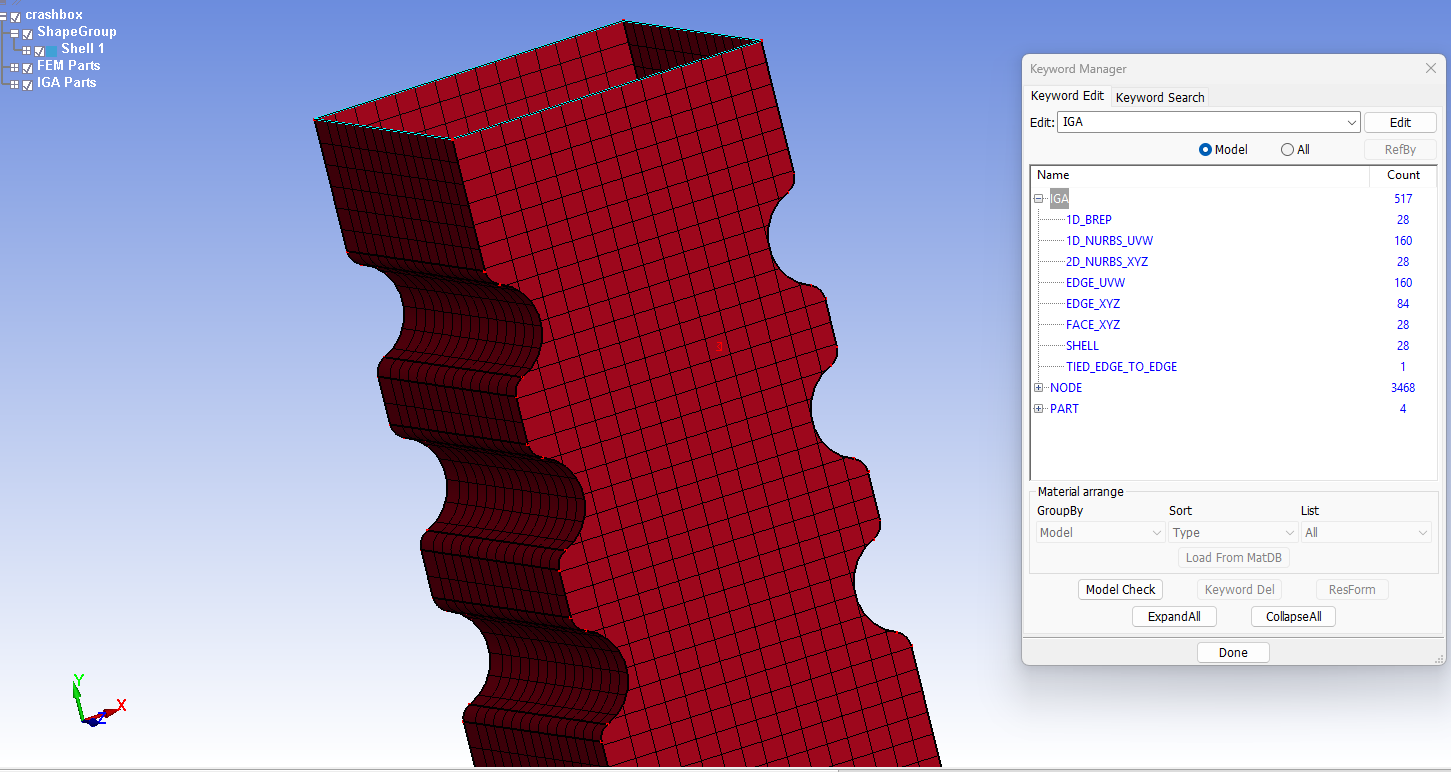

Leverage Ansys Mechanical, LS-DYNA, and Autodyn for detailed structural modeling, tackling stress distribution, dynamic impacts, and durability. - Expert-Level FEA Simulation Capabilities

Our specialists excel in refining simulation elements such as mesh detail, solver configurations, and material properties to deliver precise structural insights. - Enhanced Structural Optimization Techniques

Our streamlined FEA workflows enhance engineering efficiency, promoting robust design refinement, sensitivity testing, and superior performance.

Driving Innovation with FEA Expertise

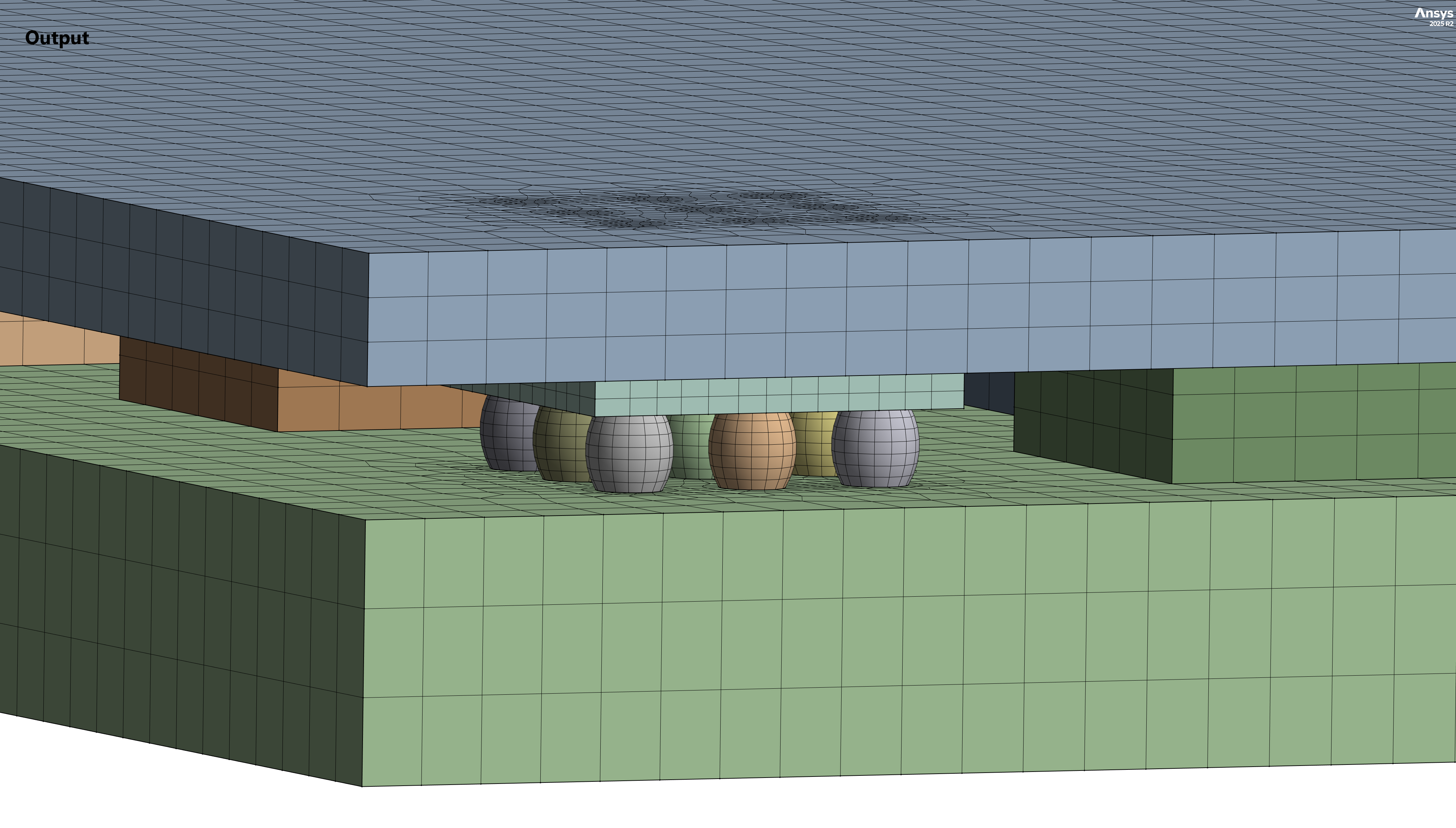

At Ozen, we deploy top-tier Ansys FEA tools—Ansys Mechanical, Ansys LS-DYNA, Ansys Autodyn, Ansys Discovery, Ansys Sherlock and Ansys Motion—to provide targeted solutions across diverse sectors. Ansys Mechanical is essential for detailed simulations such as structural integrity tests, vibration analysis, and heat transfer, boosting efficiency in semiconductor, consumer products, automotive, and aerospace industries.

Ansys LS-DYNA is renowned for its ability to model complex nonlinear events such as impacts and explosions, whereas Ansys Autodyn offers specialized capabilities for blast applications. Ansys Discovery accelerates the early stages of design through fast and flexible modeling. Ansys Sherlock provides accurate electronics reliability predictions for hardware at the component, board and system levels. And Ansys Motion excels in simulating rigid body dynamics, providing precise analysis for mechanical systems.

If your projects demand precision and cutting-edge FEA solutions, contact us today. Let’s collaborate to turn your engineering challenges into competitive advantages.

Structures Capabilities

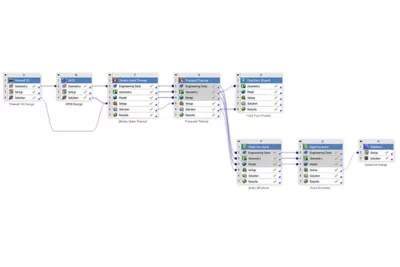

Ansys Workbench

Ansys Workbench enables connections between analysis systems. For example, a prestressed modal analysis or fluid structure analysis.

Ansys Workbench

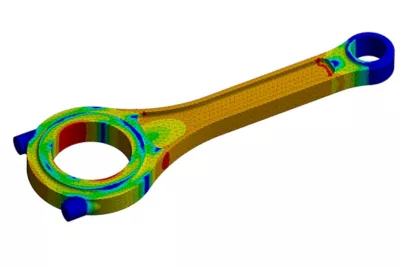

Strength Analysis

The strength of components sits as a key requirement in understanding a product’s performance, lifecycle and possible failure modes.

Strength Analysis

Vibration

Vibration can be an undesired side effect of poor product design or the environment in which the product is operating.

Vibration

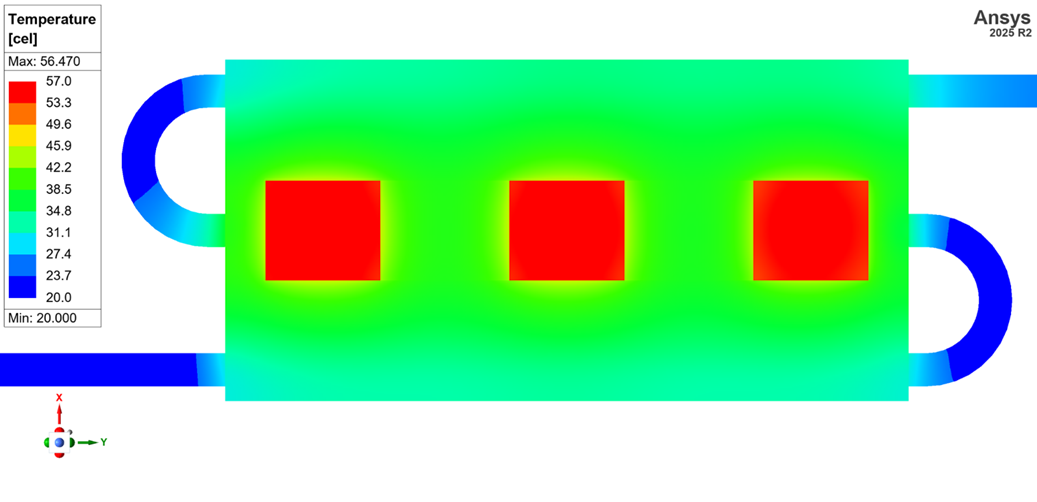

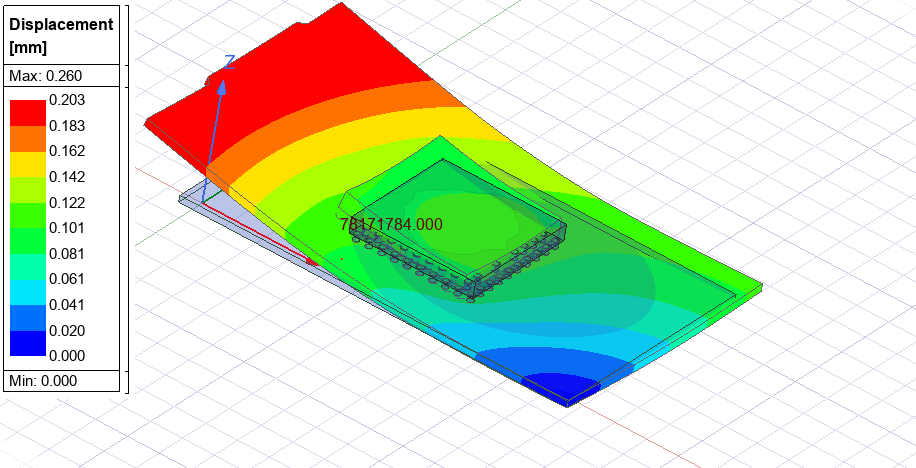

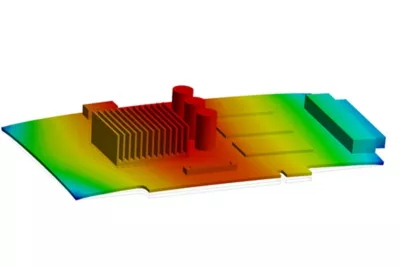

Thermal Analysis

The effects of heat and thermal management on parts and assemblies is becoming increasingly critical as performance limits are pushed further by the need to have lighter, smaller and more efficient designs.

Thermal Analysis

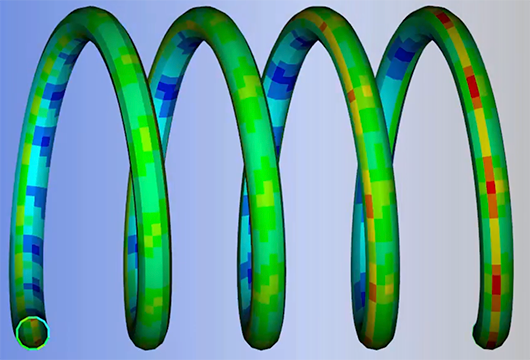

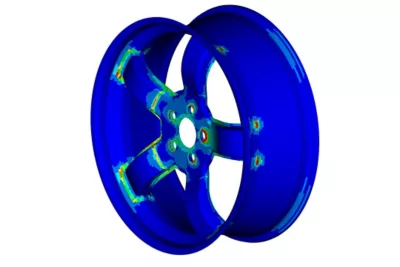

Durability

Building durable products is key to reducing warranty costs and increasing reliability. Being able to understand how designs will behave over time as load cycles increase helps you avoid unexpected failures.

Durability

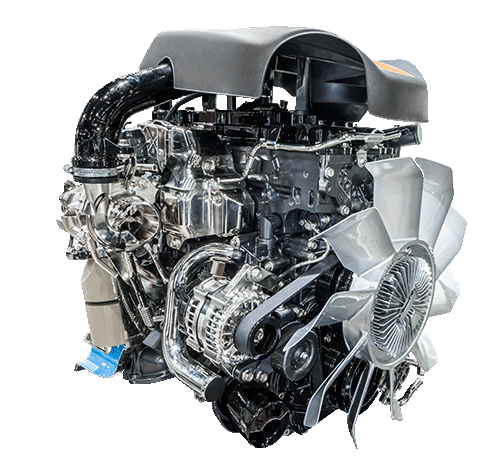

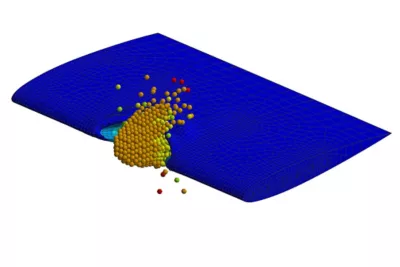

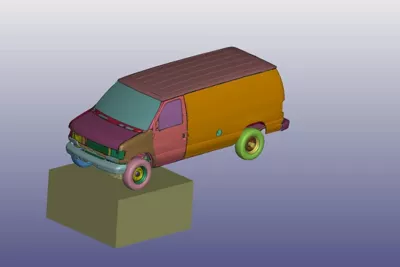

Impact

Impact between two or more bodies is modeled by the Ansys structural family of programs, including mechanical, explicit dynamics and rigid body dynamics.

Impact

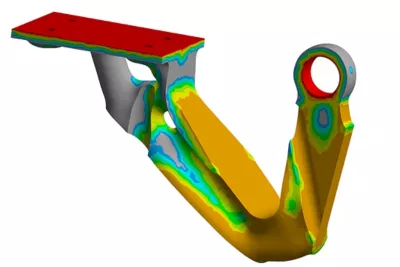

Structural Optimization

Ansys optimization technology includes parametric, shape (mesh morphing) and topology optimization.

Structural Optimization

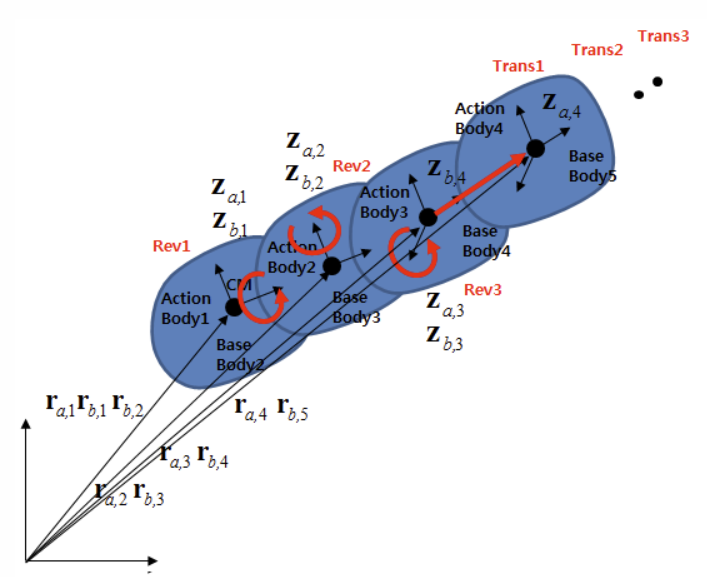

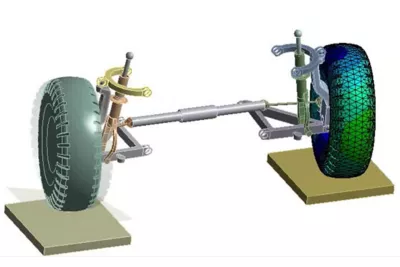

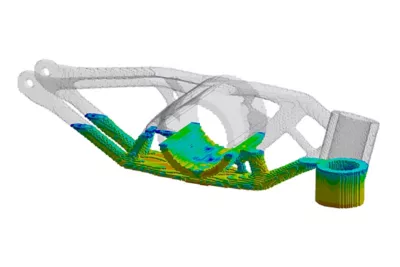

Rigid and Multi Body Dynamics

Mechanical devices can contain complex assemblies of interconnected parts undergoing large overall motions.

Rigid and Multi Body Dynamics

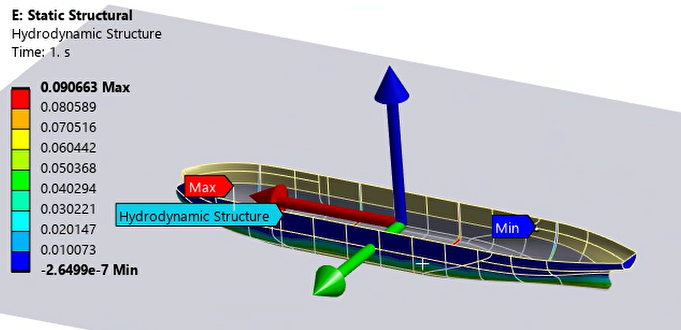

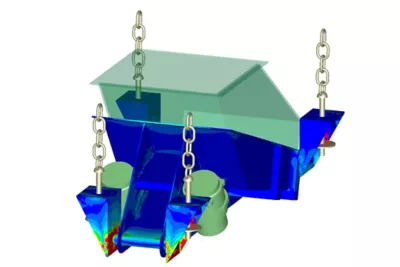

Hydrodynamics

Offshore structures are subjected to environmental loading from the effects of waves, currents and wind.

Hydrodynamics

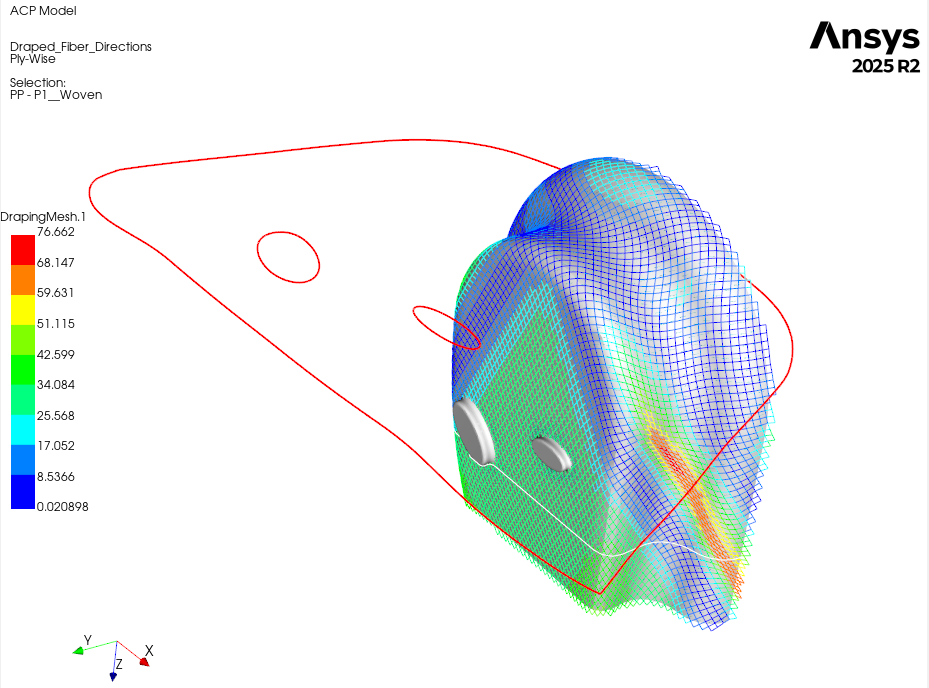

Composites

The light, strong and versatile properties of composite materials make them attractive for many types of manufacturing.

Composites

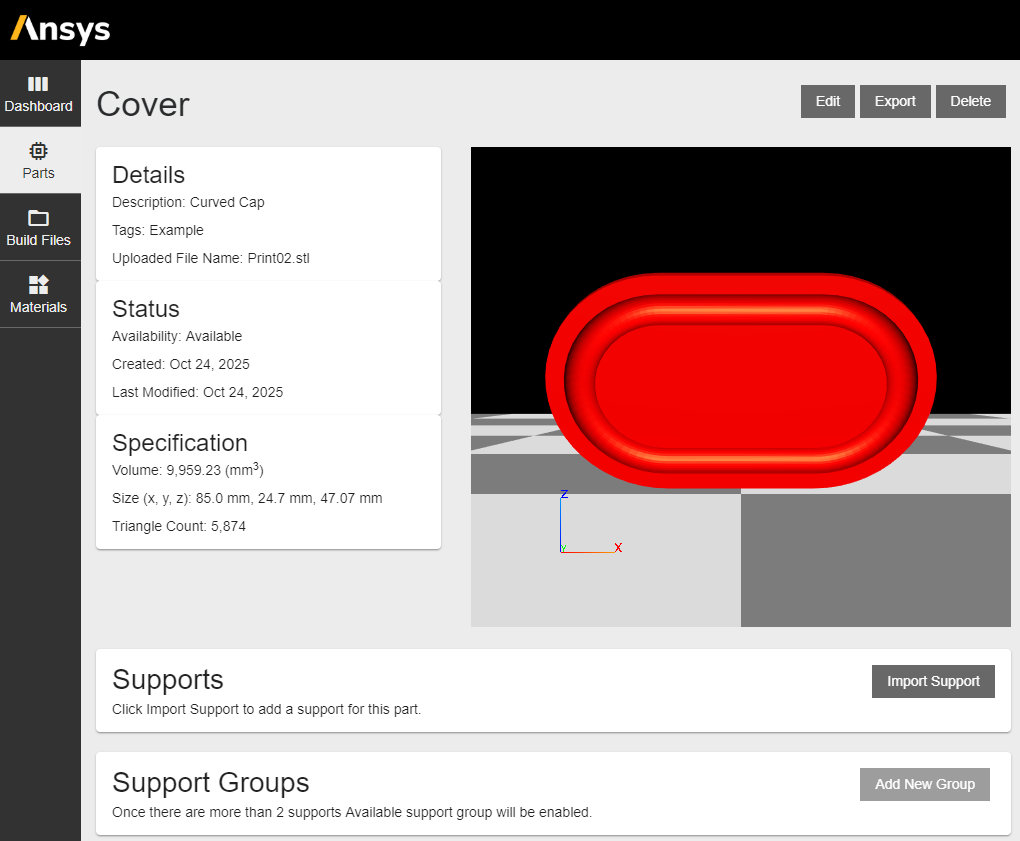

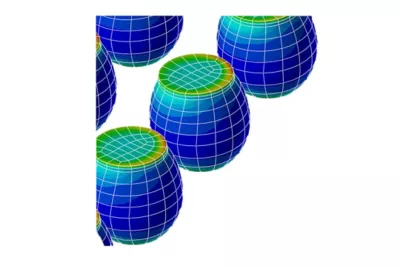

Additive Manufacturing

Ansys Additive Solution delivers the critical insights required by designers, engineers and analysts for a successful Additive Manufacturing Process, to avoid build failures and create parts that accurately conform to design specifications.

Additive Manufacturing

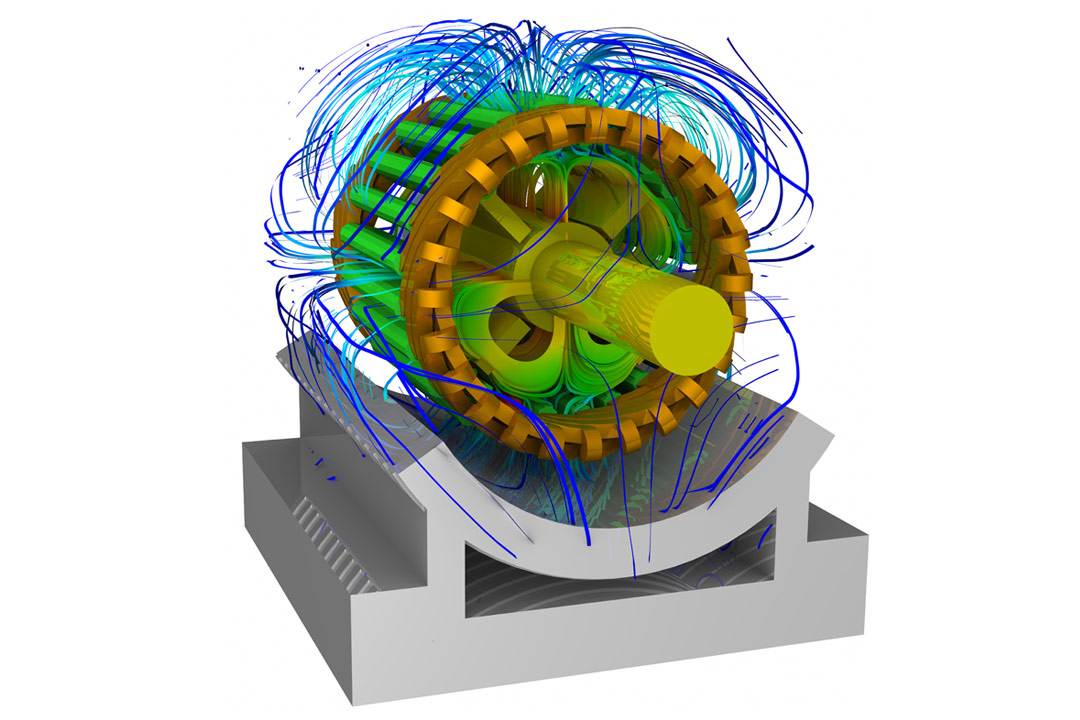

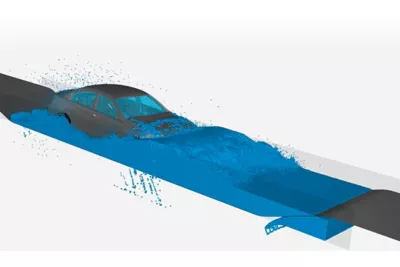

Multiphysics

A vast range of multiphysics capabilities from simple thermal structural analysis to coupled field analyses using finite element analyses are available.