Space Systems:

Accelerating Innovation for Space Missions

Space exploration and satellite missions demand unmatched precision, reliability, and safety—factors that simulation can decisively enhance. Ansys provides comprehensive simulation solutions designed specifically for the unique challenges facing the space industry, including spacecraft design, launch vehicle engineering, and satellite mission planning.

Space exploration faces unique challenges: extreme environmental conditions, rigorous safety standards, costly testing, and the critical need for mission success on the first attempt. By leveraging Ansys simulation tools, engineers can rapidly identify and solve problems early in the development cycle, reducing physical prototyping costs and accelerating time-to-launch.

Tackle Complex Space Challenges with Confidence:

Spacecraft and Satellite Design

Simulate structural integrity under extreme temperatures, radiation, vibration, and vacuum conditions, ensuring optimal reliability and reducing physical testing costs.

- Launch Vehicle Engineering:

Address critical design issues, such as structural integrity, thermal protection, and fluid dynamics, through comprehensive simulations that predict performance under realistic launch conditions. - Satellite Performance and Reliability:

Model detailed operational scenarios, including thermal management, electromagnetic compatibility (EMC/EMI), RF interference, and structural vibrations, ensuring satellites perform reliably over extended missions.

Specialized Ansys Simulation Tools for Space

Ansys offers specialized simulation tools tailored to the diverse and rigorous requirements of space missions, enabling engineers to confidently design, test, and validate spacecraft components and systems virtually. From electrostatic discharge analysis to thermal management and structural integrity, these tools ensure your space projects succeed under demanding conditions.

Electrostatic Discharge (ESD) Analysis: EMA3D Charge

- Spacecraft Charging Analysis: Crucial for assessing and mitigating spacecraft charging effects caused by space radiation and plasma environments, preventing electrostatic discharge (ESD) damage to electronics and sensitive instrumentation

Electromagnetics and RF Systems: HFSS, SIwave, EMA3D Cable

- HFSS: (High-Frequency Structure Simulator): Essential for spacecraft antenna design, ensuring high-performance RF systems, reliable communications, radar accuracy, and electromagnetic compatibility (EMC) compliance.

- SIwave: Ensures signal and power integrity in spacecraft PCBs, reducing noise, interference, and optimizing power distribution.

EMA3D Cable: Simulates EMC and EMI in spacecraft cable harnesses, critical for ensuring reliability in harsh space environments.

Fluid Dynamics, Thermal Management & Structural Integrity: Fluent, Thermal Desktop, Mechanical

- Fluent: Simulates propulsion systems, rocket engines, thrusters, and life support system airflow, ensuring proper fuel management and spacecraft thermal management.

- Thermal Desktop: Predicts thermal conditions in spacecraft and satellites, performing radiation heat transfer analysis to prevent overheating and component failure.

Mechanical: Evaluates structural integrity, vibration, and durability under launch and orbital conditions, ensuring spacecraft resilience and validating materials against mechanical stress and fatigue.

Electronics Reliability & Electromechanical Simulation: Sherlock, SIwave, Maxwell

- Sherlock: Predicts reliability, durability, lifecycle, and electronic failure risks from vibration and thermal stress in electronic assemblies and PCBs.

- Siwave: Supports power and signal integrity in spacecraft communications, preventing electromagnetic interference.

- Maxwell: Essential for designing motors, actuators, and electromagnetic components in satellite deployment mechanisms, reaction wheels, and electric propulsion systems, conducting comprehensive magnetic analysis for spacecraft attitude control.

Case Studies: Real-World Success Stories

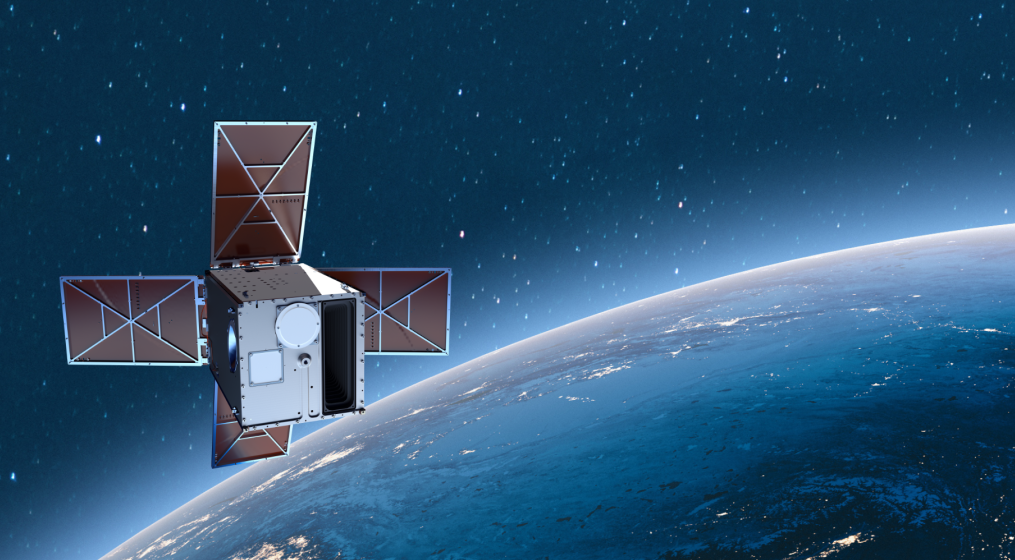

Fleet Space Technologies

Fleet Space Technologies utilized Ansys simulation software to fundamentally transform their satellite design process. By leveraging Ansys solutions, they significantly reduced the time-to-market and manufacturing costs, simultaneously enhancing reliability and robustness of their satellite missions. This enabled them to rapidly scale operations and achieve remarkable efficiency.

Anywaves: Achieving Excellence in 5G Satellite Antennas

Anywaves utilized Ansys simulation capabilities to design compact and highly efficient antennas tailored specifically for the rigorous demands of 5G satellite applications. Through virtual prototyping, they achieved significant reductions in development timelines and ensured strict compliance with industry standards, positioning themselves as a leading innovator in satellite communication technology.

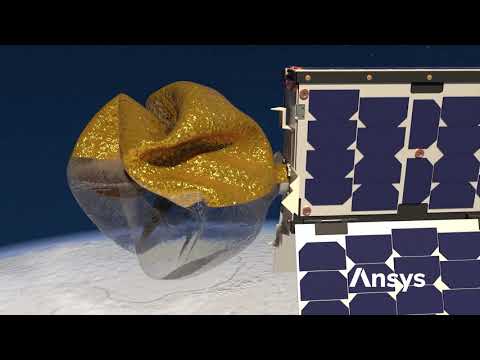

Space Forge: In-Orbit Manufacturing

Space Forge is pioneering in-orbit manufacturing using Ansys simulations to tackle complex engineering challenges. By simulating various in-orbit manufacturing processes, Space Forge successfully demonstrated how virtual prototyping significantly reduced risks, enabling more sustainable, reliable, and economically viable production methods in space.

Axiom Space: Simulations for Human Spaceflight

Axiom Space leverages Ansys simulations to drive innovation in human spaceflight endeavors. Their use of simulation technology enables rigorous testing of spacecraft structures, environmental control, and life support systems, significantly enhancing astronaut safety and mission success. This approach accelerates design cycles, reduces reliance on costly physical testing, and ensures safety and performance standards are consistently met for human missions in space.

Simulation-Driven Design for Mission Assurance

With Ansys simulation solutions, space industry companies minimize risks by virtually testing and validating designs under realistic conditions. Simulation enables teams to predict failures, optimize performance, and meet stringent industry standards efficiently, reducing costly redesigns and time-consuming physical testing.

How Ansys Empowers Space Innovators:

Reduce Time-to-Launch: Identify and correct design issues before costly physical prototyping.

Enhance Reliability: Predict and mitigate potential points of failure to increase mission success.

Optimize Performance: Achieve optimal spacecraft and subsystem designs through iterative virtual testing.

![Ansys-elite-channel-partner-horizontal-reversed[1]](https://www.ozeninc.com/uploads/2022/06/Ansys-elite-channel-partner-horizontal-reversed1.png)